Logeye Stereo: Combining traditional knowledge with MiCROTEC's solutions

With its headquarters in Sonntag (Vorarlberg, Austria) Erhart Holz is a sawmill processing logs with large diameters, mainly Austrian mountain spruce, silver fir, larch, and beech. The company is outfitted with state-of-the-art machines, such as with a drying chamber, cutting and planing equipment.

Everything started in 1954 when Adolf Erhart, equipped only with a portable sawmill, founded the company in Sonntag, Austria. Soon after, a bandsaw mill was built on this area – the first one of its kind in Austria. Numerous plant expansions and technological investments followed. The second generation of the family now runs the family business, the brothers Joachim and Ignaz Erhart. For its bandsaw line, the sawmill Erhart Holz has invested, as part of an extensive modernization program, in Microtec scanner solutions.

A few years ago, while installing the saw line, the 3D log measurement system of Microtec, Logeye 301D, was installed on the saw infeed. By using laser triangulation, the dimension-measuring scanner Logeye 301D creates a complete 3D reconstruction of a log. The 3D measurement data of this input measurement are used not only for determining a precise input statistic, but also for the cutting on the log bandsaw.

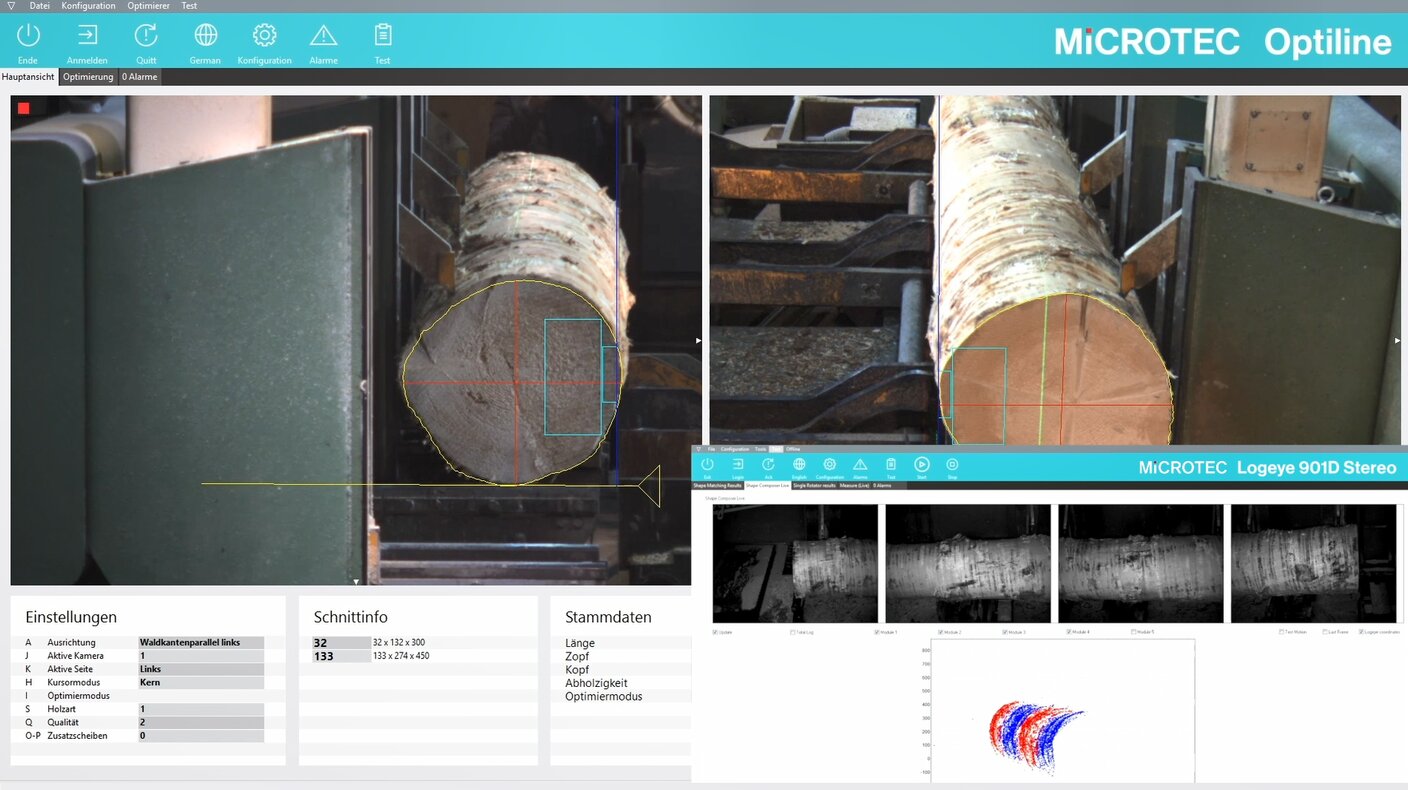

A Microtec Logeye 901 Stereo has been installed on the bandsaw. It is a stereoscopic-based system for measuring logs on the bandsaw carriage. High-resolution digital cameras and powerful LED lights are used to capture images from different perspectives. The digital image processing software determines the 3D coordinates and generates a three-dimensional spatial representation of the outer bark surface of logs.

The Logeye 901 Stereo determines the log position (rotation and longitudinal alignment) directly on the band saw carriage. It is not necessary to move the carriage to determine the 3D profile of the outer bark surface. The values, measured by the Logeye 901 Stereo on the band saw carriage, are compared with the 3D data of the Logeye 301D input measurement to determine the current position of the log on the carriage. Subsequently, the 360° 3D data of the Logeye 301D input measurement are used for optimization.

In addition to this image-matching function, the new Logeye 901 Stereo stereoscopy measurement provides a 360° measurement of logs on the band saw carriage by rotating them around their axis.

For the forward-looking sawmill Erhart Holz, the Logeye 901 Stereo has the main advantage of creating an accurate 360° log profile even for logs which, due to their diameter, cannot be transported via a saw infeed, but via an external infeed and then directly to the bandsaw.

This Microtec stereoscopic measurement is an attractive solution for bandsaw mills, which, due to the spatial limits of their plants and/or buildings, cannot install a continuous measurement at the saw infeed. Now the Logeye 901 Stereo also allows these sawmills to perform a 360° log measurement directly on the bandsaw carriage while achieving maximum yield.