Maximize your recovery and final product value

Use the most accurate scanning data provided by MiCROTEC scanners to maximize the value of the cut. Maxicut computes the best cutting solution for each log based on the production plans of the customer. Recovery is maximized and when in pair with the CT Log, the optimization is based on the final predicted quality of the boards.

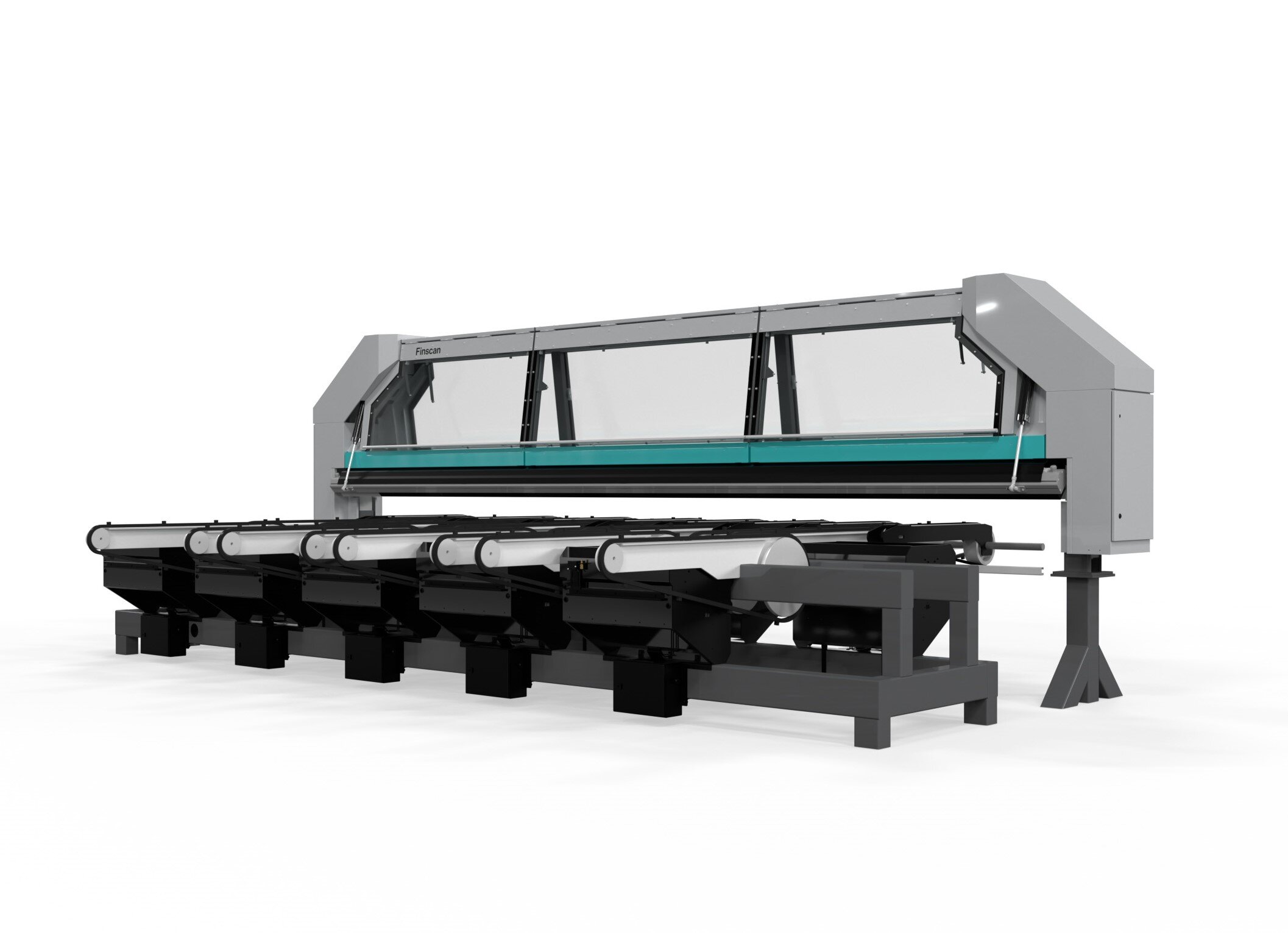

Vast integration with machines and breakdown techniques

MiCROTEC experience covers several applications. Maxicut can implement the cutting strategy according to different machine capabilities. This makes the Maxicut to be the best cutting optimizer for most sawing lines and applications.

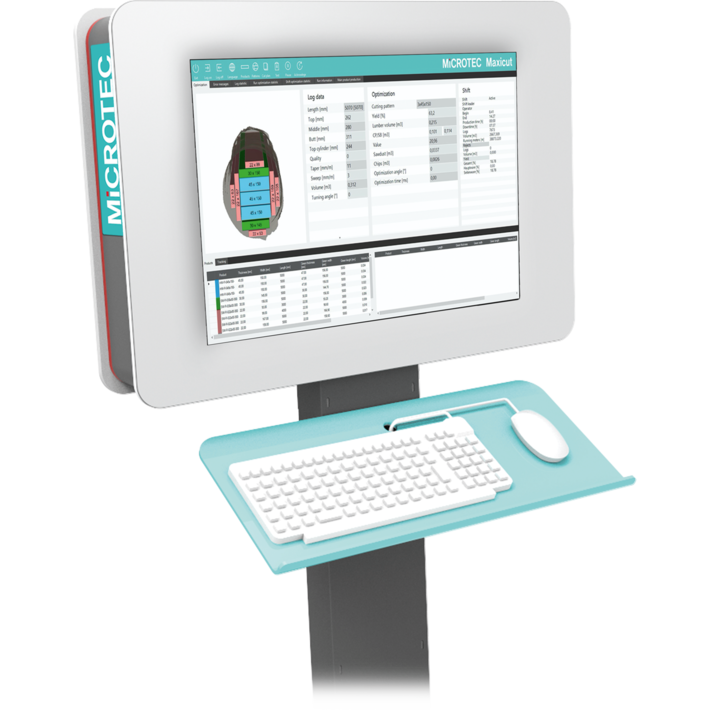

Ease the complexity

Maxicut combines powerful and flexible cutting optimization and easy usability. The modular user interface can be adjusted to the customers' needs.

Overview chart

Applications

- Sorting

- Cutting optimization

Options

- Maxicut simulation suite

Contact form