The best cutting strategy

The CT Log scanner provides the size and location of each internal defect of the log, allowing the Maxicut Pro cutting optimizer to find the best cutting solution by grading each virtual board in advance. This not only maximizes the value of the final products, but also creates a virtual stock of boards. You know exactly which boards you will produce at your logyard before cutting!

Value uplift increase starting from 5%

CT Logs around the world are installed in different lines for different applications and wood species. Depending on the sawmill's production, the value uplift provided by the CT Log starts from 5% to more than 20%.

MiCROTEC Connect

As a part of the MiCROTEC Connect solution, CT Log is the starting point for the identification of each log and board throughout the whole production process. CT Log predicts the quality of each board.

Powered by MiCROTEC Ai

Artificial Intelligence (Deep Learning AI) is integrated into all quality scanners from log to finished board. The AI knowledge of all MiCROTEC companies is merged into the MiCROTEC Ai platform, raising the possibilities of Deep Learning AI in the wood industry to a completely new level.

Overview chart

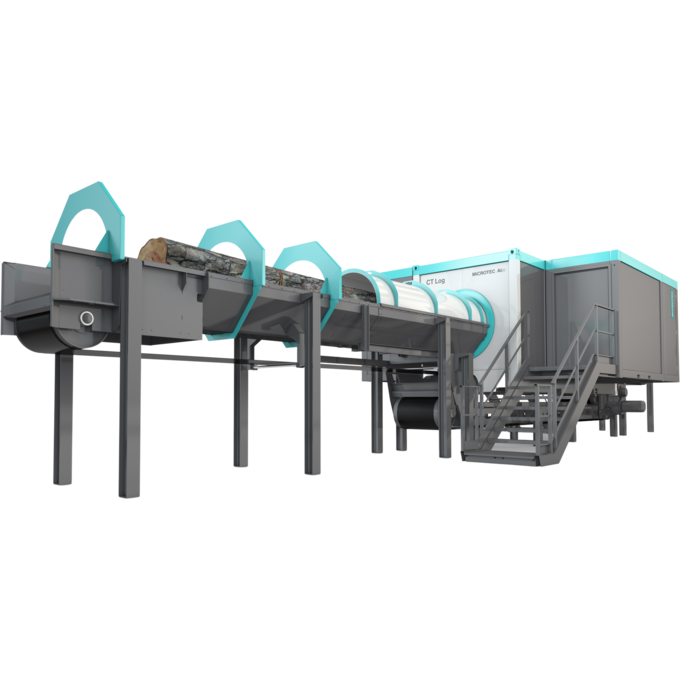

Technology

- X-ray

- Computed Tomography

- MiCROTEC Ai

Technical Data

- Pass-through diameter 900mm (34")

- Speed up to 180 m/min (600FPM)

Applications

- Sorting and grading

- Bucking

- Cutting optimization

- Fingerprint

Features

- Full 3D log description

- Quality grading

- Strength grading (optional)

- Cutting optimization

- MiCROTEC Connect

Options

- Simulation Suite

Customer Quote

Contact form