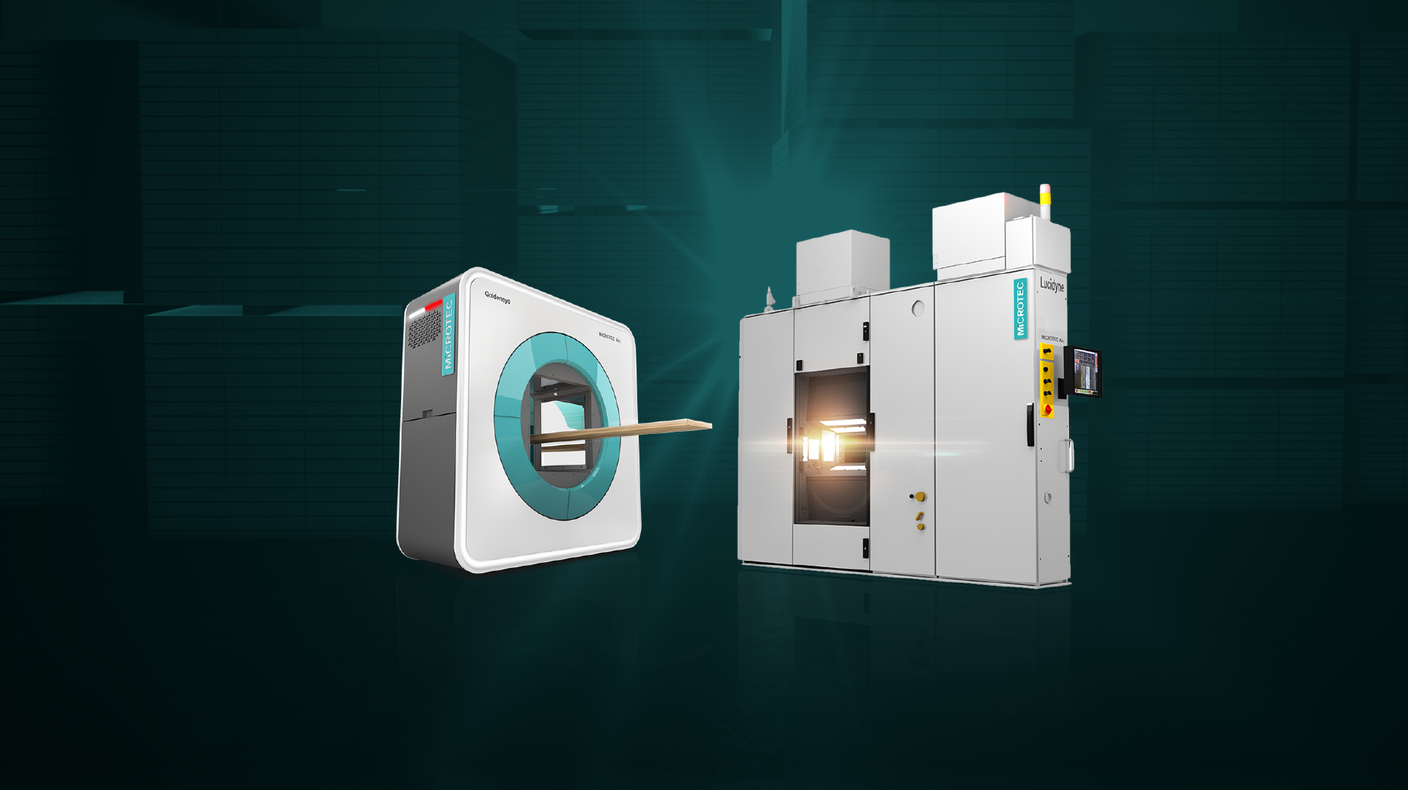

Navigating the Softwood Sector with AI-Powered Solutions: MiCROTEC's Goldeneye and Lucidyne

Navigating the Softwood Sector with AI-Powered Solutions: MiCROTEC’s Goldeneye and Lucidyne

Adapting to the dynamic needs in the softwood industry, MiCROTEC offers enhanced efficiency, precision, and a whole new level of defect detection. While North America is well-acquainted with the high-performance and high-speed lineal scanning of Lucidyne for planer mills, the arrival of Goldeneye for green, dry, and planer mills marks a pivotal moment in the softwood sector. As technology continues to advance, these solutions are poised to revolutionize mill operations, introducing a new era of precision, optimization, and profitability for green, dry, and planer mills.

Goldeneye: Changing the Game in Softwood Scanning

Operating at speeds up to 1500 feet per minute (FPM), Goldeneye’s cutting-edge multi-sensor quality scanner answers the industry’s demand for an efficient yet high-precision solution. Enhancing yield and delivering precise scanning, Goldeneye maximizes efficiency without compromising on quality.

For the past decade, Goldeneye has operated sucessfully in North American secondary processing mills. With developing technology, Goldeneye now meets NGR standards in green, dry, and planer mills as well. What truly distinguishes Goldeneye is its efficient scanning technology without compromising on quality. By streamlining processes and automation, Goldeneye minimizes waste, optimizes resource utilization, and ultimately propels the softwood industry towards a more sustainable and efficient future.

Lucidyne: A Trusted Pioneer in Lumber Grading

A trusted pioneer in lumber grading, the Lucidyne scanner is MiCROTEC’s answer for high-speed lineal scanning. Bolstered by the capabilities of MiCROTEC Ai, the Lucidyne is engineered to grade lumber with high precision and is tailored to high-speed planer mills at speeds up to 4500 FPM. What sets the Lucidyne apart is its unrivaled uptime in the industry, ensuring maximum fiber recovery and value. The uptime of Lucidyne translates to minimal production disruptions, resulting in reduced downtime costs and optimized operational efficiency.

MiCROTEC's Goldeneye and Lucidyne are set to propel the North American softwood sector to unprecedented levels of efficiency and quality. By embracing these AI-powered solutions, and specifically MiCROTEC’s proprietary technology, MiCROTEC Ai, the softwood industry stands at the forefront of a future where precision, sustainability, and profitability meet innovation.

QC Assist: Enhancing Quality Control

QC Assist, designed to further improve the efficiency and quality of lumber grading seamlessly integrates with the Goldeneye and Lucidyne, supporting overall grading performance. The tool facilitates smooth communication with the scanners, empowering users to easily verify and document boards of interest during the quality control process. It also serves as a link to the MiCROTEC grading support team, which optimizes the defect detection process.

Originally introduced with the Lucidyne, QC Assist has now become an integral part of the Goldeneye as well, ensuring that the softwood industry benefits from advanced quality control and defect detection while optimizing operational efficiency. As the industry embraces AI-powered solutions like MiCROTEC’s proprietary technology, MiCROTEC Ai, it sets new standards for softwood production.

Goldeneye and Lucidyne are supported locally by the MiCROTEC grading support team.